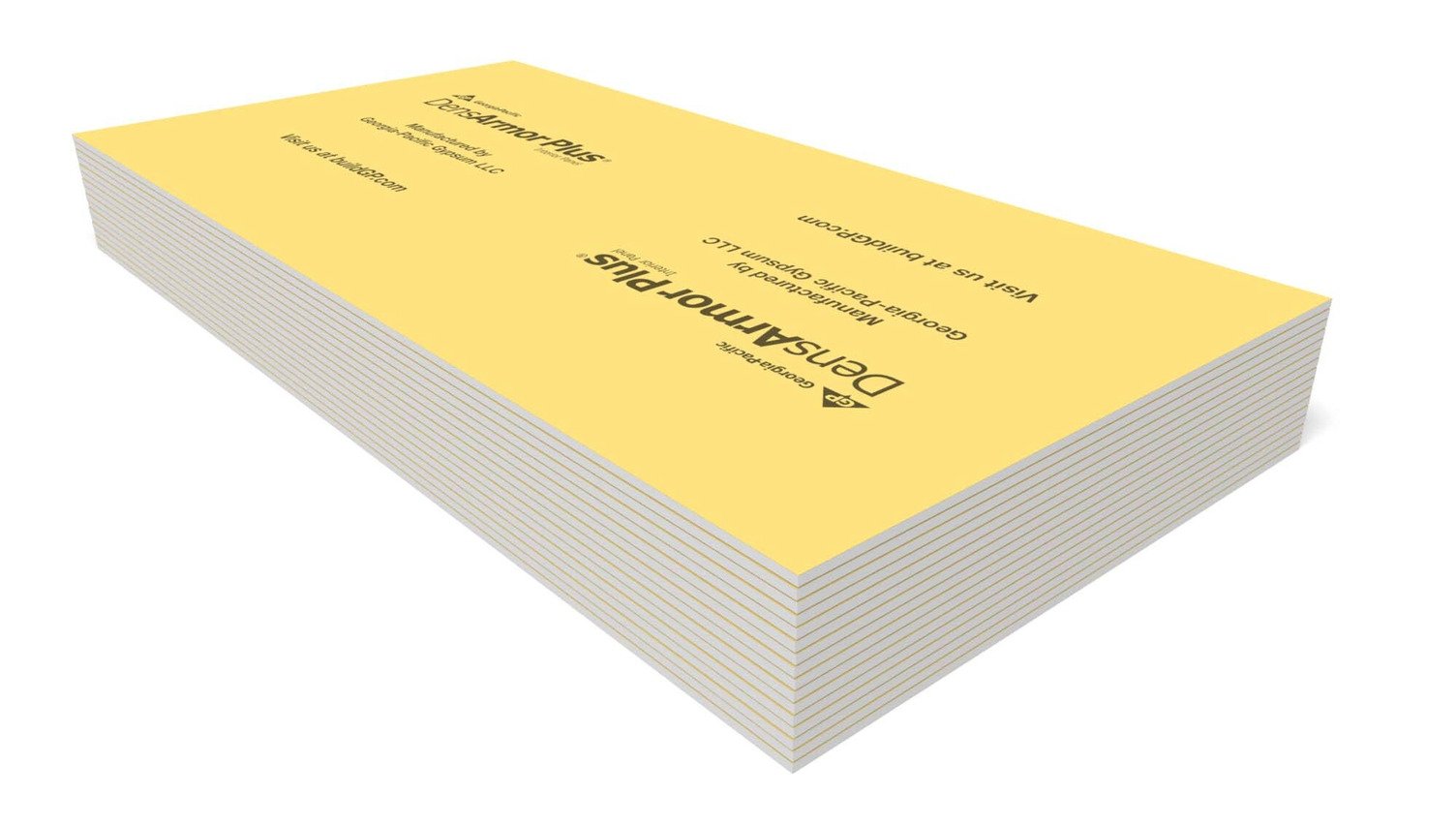

DensArmor Plus® Interior Panel

- Designed with a moisture-resistant gypsum core and fiberglass mats, providing protection against mold, mildew, and deleterious effects after exposure to moisture.1

- A top choice for areas prone to moisture, such as residential basements, bathrooms, or commercial installations.

Product Details

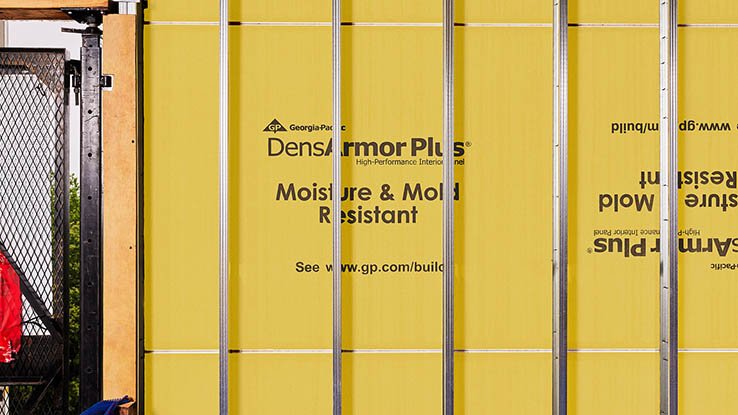

DensArmor Plus® Interior Panels are the solution for durable, mold-resistant interiors These panels are designed with a moisture-resistant gypsum core and fiberglass mats, providing protection against mold, mildew, and deleterious effects after exposure to moisture.”. Tested to the highest standard (ASTM D3273), they scored a 10 for mold resistance, making them a reliable choice for areas prone to moisture, like residential basements or bathrooms or commercial installations.

These interior panels also deliver dimensional stability with their reinforced fiberglass core. They resist warping, rippling, and buckling far better than regular gypsum boards. These panels are versatile enough to attach directly to wood or metal framing or even existing surfaces.

The mold resistance of any building product when used in actual job site conditions may not produce the same results as were achieved in the controlled, laboratory setting. No material can be considered mold proof. When properly used with good design, handling and construction practices, DensArmor Plus® Interior Panels provide increased mold resistance compared to standard paper-faced gypsum products.

FEATURES AND BENEFITS

- Superior Moisture Resistance: Made with a moisture-resistant gypsum core and fiberglass mats, perfect for high-moisture areas like interiors of exterior walls and wet areas behind tiles.

- Long-lasting Durability: Reinforced fiberglass core resists warping, rippling, and buckling, ensuring dimensional stability and strength.

- Eco-Friendly & Low VOC: GREENGUARD and GREENGUARD Gold Certified for low VOC emissions, ensuring healthier indoor air quality. Also listed in the CHPS® High Performance Products Database.

- Customizable Finish: Tapered edges for joint treatment and compatibility with most paints and textures. Designed for a seamless finish.

- Durability: With a reinforced fiberglass core, our panels resist warping, rippling, and buckling, giving you a long-lasting solution.

- Enhanced Stability: Our panels outperform regular gypsum boards in stability, offering you a more secure option.

- Hassle-free Installation: Since our panels install just like regular wallboards, you’ll experience no unnecessary complications or difficulties.

Product Specifications

PERFORMANCE ATTRIBUTES

| R Value | °F•ft2•hr/BTU (m2•K/W: .56 (0.099) |

| Humidified Deflection 1,2 | ≤2/89 (6.4 mm) |

| ASTM Type | ASTM C518, ASTM C473, ASTM C1658, ASTM C1177, ASTM E136, ASTM E96 |

| Flame Spread & Smoke Development | 0/0 |

| Mold Resistance | No (10/10) |

| Water Absorption(% of weight) 1,2 | <5 |

PHYSICAL PROPERTIES

| Thickness 3 | nominal: 1/2″ (12.7 mm) ± 1/64″ (0.4 mm) |

| Width 3 | standard: 4′ (1219 mm) ± 3/32″ (2.4 mm) |

| Length 3 | standard: 8′ (2438 mm) to 12′ (3658 mm) ± 1/4″ (6.4 mm) |

| Weight | lbs/sq. ft. nominal (kg/m²): 2.0 (9.8) |

| R Value | °F•ft2•hr/BTU (m2•K/W): .56 (0.099) |

| Humidified Deflection | ≤2/8″ (6.4 mm) |

PERFORMANCE ATTRIBUTES

| R Value | °F•ft2•hr/BTU (m2•K/W: .67 (0.118) |

| Humidified Deflection 1,2 | ≤1/89 (3 mm) |

| ASTM Type | ASTM C518, ASTM C473, ASTM C1658, ASTM C1177, ASTM E136, ASTM E96 |

| Flame Spread & Smoke Development | 0/0 |

| Mold Resistance | No (10/10) |

| Water Absorption(% of weight) 1,2 | <5 |

PHYSICAL PROPERTIES

| Thickness 3 | nominal: 5/8″ (15.9 mm) ± 1/64″ (0.4 mm) |

| Width 3 | standard: 4′ (1219 mm) ± 3/32″ (2.4 mm) |

| Length 3 | standard: 8′ (2438 mm) to 12′ (3658 mm) ± 1/4″ (6.4 mm) |

| Weight | lbs/sq. ft. nominal (kg/m²): 2.5 (12.2) |

| R Value | °F•ft2•hr/BTU (m2•K/W): .67 (0.118) |

| Humidified Deflection | ≤1/89 (3 mm) |

Specific products may not be available in all markets. Contact your sales representative for product availability

1. Tested in accordance with ASTM C473

2. Specified values per ASTM C1658 and ASTM C1177

3. Specified values per ASTM C1658 and ASTM C1177

CERTIFICATIONS

Resources

FAQs

Yes; any interior wall, basement wall, laundry room or ceiling that is in an area prone to high humidity are sound applications. DensArmor Plus® panels should not be used on Exterior Walls.

No. DensArmor Plus® panels should not be used on exterior applications. See DensGlass® Sheathing.

Yes, DensArmor Plus® panels are suitable for soffit applications where it is not exposed directly to the elements. It can be finished using a setting-type joint compound prior to priming and painting.

Related Products

Need Technical Help?

Gypsum Products

OSB/Plywood Products

Wood Products

Lumber Products

Newsletter Sign Up

Subscribe for the latest news and insights.