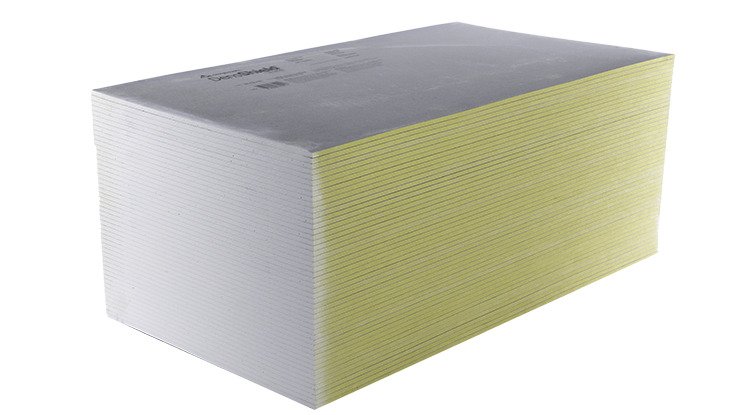

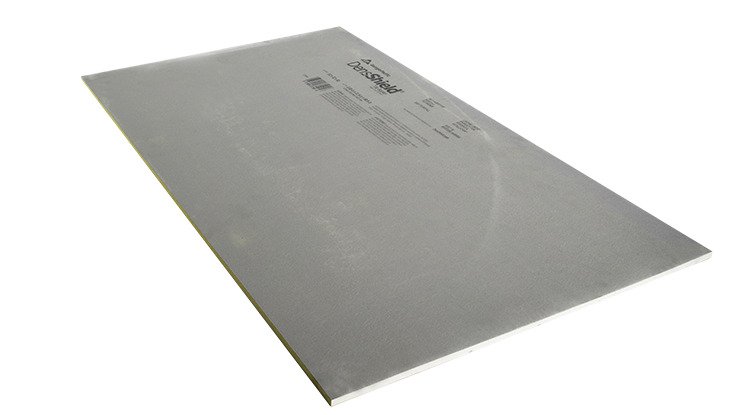

DensShield® Tile Backer

- Designed with a built-in moisture barrier to protect wall cavities and wood subfloors.

- Saves time and effort vs cement board.

- Scores & snaps and installs using standard tools, unlike cement board that requires specialized tools and fasteners.

- Unique moisture-resistant core outperforms cement backers in protecting walls, floors, and ceilings in wet, high-humidity areas.

Product Details

DensShield® Tile Backer is your solution to tile underlayment in any new construction or remodeling project. This versatile product is perfect for a range of environments, from wet areas such as bathrooms and indoor pools to locations with high humidity1, and even in places that aren’t wet, offering ease in priming and painting in instances where tile isn’t employed on top of it.

DensShield® Tile Backer offers easier handling than traditional cement board. You can cut it effortlessly, eliminating the need for specialized tools or fasteners. This product is also available as a 5/8″ Type X board (as per ASTM C1178), perfect for fire-rated assemblies. Compliance with the requirements of the 2009 IBC/IRC Code for tile backer used in wet areas is another feature that sets DensShield® Tile Backer apart.

Dens® Solutions are industry trusted, high-performing fiberglass mat gypsum panels suitable for your wall, roof, ceiling and floor projects. Dens® Suite of Gypsum Products carry the mark of our valued heritage in Gold, as a visible standard-bearer of our position as the first manufacturer to create a fiberglass mat board and as a relentless innovator of strength and moisture resistant products for over 30 years. Dens® Suite of Gypsum Products answer building challenges with ingenuity.

FEATURES AND BENEFITS

- Mold & Moisture Resistance: The fiberglass mat board, which stops moisture under ASTM D3273, features a water-resistant treated core and a built-in moisture barrier, eliminating the need for an additional one and proficiently protecting wood sub floors and wall cavities from water and mold.1

- Easy to Install: 20% lighter than cement and 25% lighter with fiber cement, making installation a breeze.2

- Fire Safety Certified: 5/8″ DensShield® Fireguard Tile Backer meets UL and ULC fire resistance standards, making it suitable for use in fire-rated wall assemblies.

Product Specifications

PERFORMANCE & PHYSICAL ATTRIBUTES

| Thickness | 1/4″ (6.4 mm) |

| Width x Length | 4′ x 4′ (1220 mm x 1220 mm) |

| ASTM Type | ASTM C1178, ASTM D3273 |

| Edges | Square Edge |

PERFORMANCE & PHYSICAL ATTRIBUTES

| Thickness | 1/2″ (12.7 mm) |

| Width x Length | 32″ x 5′ (813 mm x 1524 mm) 4′ x 5′ (1220 mm x 1524 mm) 4′ x 8′ (1220 mm x 2438 mm) |

| ASTM Type | ASTM C1178, ASTM D3273 |

| Edges | Square Edge |

PERFORMANCE & PHYSICAL ATTRIBUTES

| Thickness | 5/8″ (15.9 mm) |

| Width x Length | 4′ x 8′ (1220 mm x 2438 mm) |

| ASTM Type | ASTM C1178, ASTM D3273 |

| Edges | Square Edge |

CERTIFICATIONS

Certifications may vary by production location, please contact local representative for more information.

1. DensShield® Tile Backer has scored a 10 – the highest level of performance for mold resistance under the ASTM D3273 test method. The score of 10 in the ASTM D3273 test indicates no mold growth in a 4-week controlled laboratory test. The mold resistance of any building product when used in actual job site conditions may not produce the same results as were achieved in the controlled, laboratory setting. No material can be considered mold proof. When properly used with good design, handling and construction practices, DensShield Tile Backer provides increased mold resistance compared to standard paper-faced wallboard products. The mold resistance of DensShield Tile Backer has been validated by UL Environmental. Learn more about UL Environmental claims validation at ul.com/ecv.

2. Source: Installation Guide for DUROCK® Cement Board (Lit#CB237EN; Printed 11/11); Submittal Sheet for DUROCK® Cement Board (Lit #CB399; Print 11/11)

Resources

FAQs

No special or unique fasteners are required to fasten DensShield® Tile Backer panels in place. For wood studs: galvanized roofing nails, rust-resistant drywall screws or bugle head deck screws. Fasteners should be long enough to penetrate at least 3⁄4 (19 mm) into the wood framing members. For metal framing: a variety of rust-resistant screws can be used.

Yes. The DensShield® Tile Backer panel should be positioned next to framing with the acrylic coated (grey) side facing away from studs. Apply mortar or mastic and tile to the acrylic coated (grey) side of DensShield® Tile Backer panels. The built-in acrylic coating stops moisture penetration at the surface.

While gypsum boards are stronger in one direction, they may be installed either vertically or horizontally on both wood and steel studs. If the boards are to be used in a fire rated assembly, then use the board orientation that is stated in your specific rated assembly.

Related Products

Need Technical Help?

Gypsum Products

OSB/Plywood Products

Wood Products

Lumber Products

Newsletter Sign Up

Subscribe for the latest news and insights.