Blue Ribbon® Sturd-I-Floor

- Wood Structural Panel made from primarily sustainable southern yellow pine or northern aspen & mixed hardwoods, edge protected from moisture with Blue Edge Seal.

- Well suited for direct application of carpets and pads as well as hardwood flooring.

- Classified by APA as having Exposure 1 bond durability for limited exposure and protected applications.

- Exempt from the world’s leading formaldehyde emission standards and regulations due to very low emission rates

- Limited lifetime warranty

Product Details

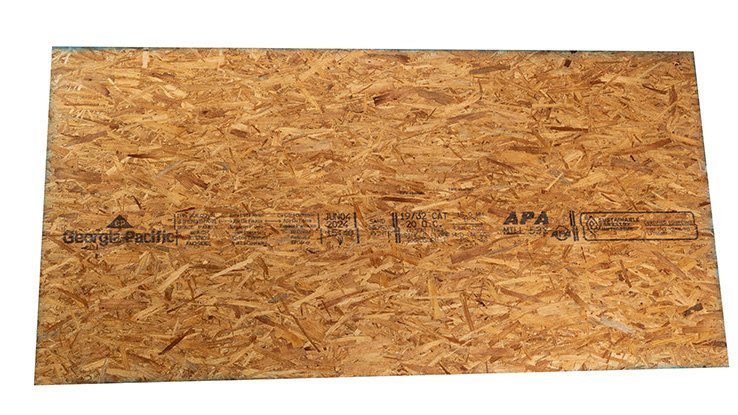

Enhance the longevity and quality of your flooring with our inimitable OSB Subfloor. This product provides remarkable strength and moisture resistance, making it a reliable choice for residential and light commercial projects. Available in both Tongue & Groove and square edge options, our subfloor is ingeniously engineered with Southern Yellow Pine and fortified with a protective Blue Edge Seal. This design offers superior defense against damage and extends the life of your flooring system.

Classified by APA as Exposure 1, our OSB Subfloor exhibits dependable durability and uniform strength. You won’t have to worry about structural weaknesses such as core voids or splits. Whether you’re working on a new project or renovating your home, our subfloor is suitable for a wide range of flooring applications.

Our commitment to quality is also reflected in our lifetime limited warranty, offering you the peace of mind you deserve when investing in our product. Moreover, our commitment to sustainability is paramount. We source wood exclusively from suppliers that are third-party certified to Sustainable Forestry Initiative (SFI#174) or Forest Stewardship Council (FSI) fiber sourcing standards, ensuring that our products contribute to the health and longevity of our forests. Invest in our OSB Subfloor for a durable, reliable, and environmentally responsible flooring solution.

FEATURES AND BENEFITS

- Durability: Engineered to withstand the toughest demands, this subfloor ensures a dependable base that lasts, no matter the project.

- Sustainable Sourcing: We care about more than just your floors—we care about the planet too. Our wood is sourced exclusively from suppliers certified by the Sustainable Forestry Initiative (SFI) and Forest Stewardship Council (FSC), supporting forest health and longevity.

Product Specifications

Performance Attributes

| Classification | Exposure 1 : OSB suitable for uses not permanently exposed to the weather. Panels classified as Exposure 1 are intended to resist the effects of moisture on structural performance as may occur due to construction delays, or other conditions of similar severity. |

| Code Fire Classification | Class III or C |

| Flame Spread Rating | 76-200, smoke developed index <450 |

| Building Code Compliance | PS 2-18 |

| Testing Agency | APA® – The Engineered Wood Association |

Physical Properties

| Square Edge | 3′-11 7⁄8″ (1.216 m) x 7′-11 7⁄8″ (2.435 m) |

| Tongue & Groove | 3′-11 1⁄2″ (1.206 m) x 7′-11 7⁄8″ (2.435 m) |

| Thickness (Category) | 19/32 CAT – 0.578″ (14.68 mm) 23/32 CAT – 0.703″ (17.85 mm) 1-1/8 CAT – 1.091″ (27.71 mm) |

| Length/Width Tolerance | ± 1/16” (± 1.6 mm) |

| Straightness Tolerance | ± 1/64” per 2 ft. of length |

| Squareness Tolerance | ± 1/16” (± 1.6 mm) |

Performance Attributes

| Classification | Exposure 1 : OSB suitable for uses not permanently exposed to the weather. Panels classified as Exposure 1 are intended to resist the effects of moisture on structural performance as may occur due to construction delays, or other conditions of similar severity. |

| Code Fire Classification | Class III or C |

| Flame Spread Rating | 76-200, smoke developed index <450 |

| Building Code Compliance | PS 2-18 |

| Testing Agency | APA® – The Engineered Wood Association |

Physical Properties

| Square Edge | 3’-11 7⁄8″ (1.216 m) x 8’-11 7⁄8″ (2.740 m) |

| Tongue & Groove | 3′-11 1⁄2″ (1.206 m) x 8′-11 7⁄8″ (2.435 m) |

| Thickness (Category) | 19/32 CAT – 0.578″ (14.68 mm) 23/32 CAT – 0.703″ (17.85 mm) 1-1/8 CAT – 1.091″ (27.71 mm) |

| Length/Width Tolerance | ± 1/16” (± 1.6 mm) |

| Straightness Tolerance | ± 1/64” per 2 ft. of length |

| Squareness Tolerance | ± 1/16” (± 1.6 mm) |

Performance Attributes

| Classification | Exposure 1 : OSB suitable for uses not permanently exposed to the weather. Panels classified as Exposure 1 are intended to resist the effects of moisture on structural performance as may occur due to construction delays, or other conditions of similar severity. |

| Code Fire Classification | Class III or C |

| Flame Spread Rating | 76-200, smoke developed index <450 |

| Building Code Compliance | PS 2-18 |

| Testing Agency | APA® – The Engineered Wood Association |

Physical Properties

| Square Edge | 3’-11 7⁄8″ (1.216 m) x 9’-11 7⁄8″ (2.740 m) |

| Tongue & Groove | 3′-11 1⁄2″ (1.206 m) x 9′-11 7⁄8″ (2.435 m) |

| Thickness (Category) | 19/32 CAT – 0.578″ (14.68 mm) 23/32 CAT – 0.703″ (17.85 mm) 1-1/8 CAT – 1.091″ (27.71 mm) |

| Length/Width Tolerance | ± 1/16” (± 1.6 mm) |

| Straightness Tolerance | ± 1/64” per 2 ft. of length |

| Squareness Tolerance | ± 1/16” (± 1.6 mm) |

CERTIFICATIONS

FSC (applies to Englehart only – Mill 530)

Resources

FAQs

Sturd-I-Floor® is an APA designation that is a combination subfloor-underlayment produced from OSB or plywood. These panels feature a built-in underlayment that allows the convenience of using only Sturd-I-Floor® under certain finish flooring, especially carpet and pad.

OSB is not recommended for outdoor projects. OSB is considered an Exposure 1 panel, which means they may be used for applications where construction delays may be expected prior to providing protection. But OSB is not suitable for long-term exposure to the weather.

The number of panels in a unit of OSB varies depending on the type and thickness of product. On sheathing products, the piece count is typically stenciled on the side of the unit. Other products have corrugated side protectors that should indicate piece count. If you need a piece count and neither of those are visible, please contact GP at 800-284-5347.

No, span ratings for similar thicknesses are the same.

Class III or C

Related Products

Need Technical Help?

Gypsum Products

OSB/Plywood Products

Wood Products

Lumber Products

Newsletter Sign Up

Subscribe for the latest news and insights.