DensDeck® Prime Roof Board

- Created for mechanically fastened, adhered, and partially adhered roofing systems.

- Designed for water resistance, allowing just 5% water absorption by weight and providing double the moisture resistant capabilities for your roof structure, adhering to the ASTM C1177 guidelines.

- Noncombustible gypsum roofboard with zero flame spread and zero smoke developed when tested in accordance with ASTM E84.

Product Details

Discover the durability of DensDeck® Prime Roof Board with EonicTM Technology, engineered with a robust fiberglass mat and high-density gypsum core. Providing top-tier fire resistance, wind uplift protection, and puncture resistance, DensDeck® Prime Roof Board is designed to withstand wear, weather, and heavy foot traffic. An ideal choice for mechanically fastened, adhered, and partially adhered roofing systems, it offers a superior bonding surface for roofing membranes and air/vapor retarders.

One of its key attributes is its extended compatibility and heightened performance with roofing adhesives. Enhanced with our patented EONIC™ Technology, DensDeck® Prime Roof Boards boast double the resistance to moisture as per ASTM C1177 guidelines. This critical feature helps protect your roof structure, maintain the integrity of your roofing assembly, and shield the contents within your building.

DensDeck® Prime Roof Board is built with exceptional water resistance, offering only 5% water absorption by weight, and a mere 1-gram nominal surface water absorption performance on both sides of the board. Choose DensDeck® Prime Roof Boards for long-lasting, resilient roofing solutions.

FEATURES AND BENEFITS

- Better Results: Improve membrane bond strength and achieve a stronger, longer-lasting roof.

- Versatile Applications: Compatible with various roofing systems and methods.

- Resilient Performance: Defends against fire, wind, punctures, and even severe hail.

- Ease of Installation: Enhanced adhesion eliminates unnecessary steps and materials.

- Water Absorption: Offers 5% water absorption resistance by weight, and 1-gram nominal surface water absorption performance on both sides of the board.

Product Specifications

PERFORMANCE ATTRIBUTES

| R Value | °F•ft2•hr/BTU (m2•K/W): .28 |

| ASTM Type | ASTM C473; ASTM E661; ASTM E96; ASTM C518; ASTM C1177; ASTM C473 |

| Flame Spread & Smoke Development | (ASTM E84): 0/0 |

| Mold Resistance | (10/10) |

| Flexural Strength, parallel, lbf. min. (N) | ≥40 (178) |

| Flute Spanability2 | 2-5/8” (66.7 mm) |

| Permeance, Perms (ng/Pa•S•m2 ) | >30 (>1710) |

| Linear Variation with Change in Temp., in/in/°F (mm/mm/°C) | 8.5 x 10-6 (15.3 x 10-6) |

| Linear Variation with Change in Moisture | 6.25 x 10-6 |

| Water Absorption, % max3 | 5 |

| Compressive Strength, psi nominal | 900 |

| Surface Water Absorption, grams, nominal | 1.0 |

| Bending Radius | 4’ (1219 mm) |

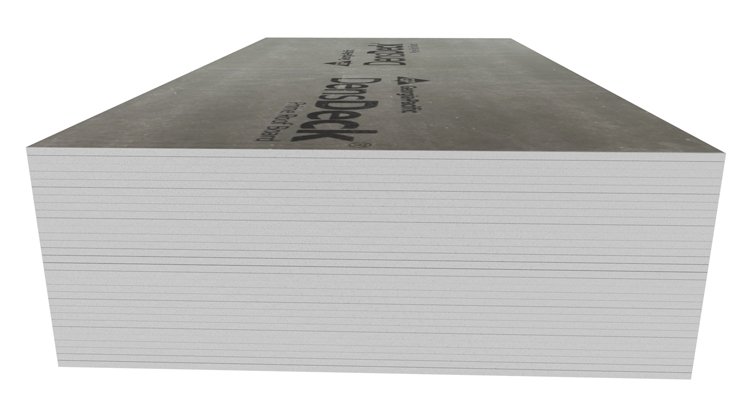

PHYSICAL PROPERTIES

| Length | standard: 4′ (1219 mm) and 8′ (2438 mm) ± 1/4″ (6.4 mm) |

| Width | standard: 4’ (1219 mm) ± 1/8” (3 mm) |

| Thickness | nominal: 1/4” (6.4 mm) ± 1/16” (1.6 mm) |

| Weight | nominal: 1.2 (5.9) |

PERFORMANCE ATTRIBUTES

| R Value | °F•ft2•hr/BTU (m2•K/W): .56 |

| ASTM Type | ASTM C473; ASTM E661; ASTM E96; ASTM C518; ASTM C1177; ASTM C473 |

| Flame Spread & Smoke Development | (ASTM E84): 0/0 |

| Mold Resistance | (10/10) |

| Flexural Strength, parallel, lbf. min. (N) | ≥80 (356) |

| Flute Spanability2 | 5” (127 mm) |

| Permeance, Perms (ng/Pa•S•m2 ) | >35 (1995) |

| Linear Variation with Change in Temp., in/in/°F (mm/mm/°C) | 8.5 x 106 (15.3 x 106) |

| Linear Variation with Change in Moisture | 6.25 x 106 |

| Water Absorption, % max3 | <10 |

| Compressive Strength, psi nominal | 900 |

| Surface Water Absorption, grams, nominal | <2.5 |

| Bending Radius | 6’ (1829 mm) |

PHYSICAL PROPERTIES

| Length | standard: 8’ (2438 mm) ± 1/4” (6.4 mm) |

| Width | standard: 4’ (1219 mm) ± 1/8” (3 mm) |

| Thickness | nominal: 1/2” (12.7 mm) ± 1/32” (.8 mm) |

| Weight | nominal: 2.0 (9.8) |

PERFORMANCE ATTRIBUTES

| R Value | °F•ft2•hr/BTU (m2•K/W): .67 |

| ASTM Type | ASTM C473; ASTM E661; ASTM E96; ASTM C518; ASTM C1177; ASTM C473 |

| Flame Spread & Smoke Development | (ASTM E84): 0/0 |

| Fire Rating | Type X |

| Mold Resistance | (10/10) |

| Flexural Strength, parallel, lbf. min. (N) | ≥100 (444) |

| Flute Spanability2 | 8” (203 mm) |

| Permeance, Perms (ng/Pa•S•m2 ) | >32 (1824) |

| Linear Variation with Change in Temp., in/in/°F (mm/mm/°C) | 8.5 x 106 (15.3 x 106) |

| Linear Variation with Change in Moisture | 6.25 x 106 |

| Water Absorption, % max3 | <10 |

| Compressive Strength, psi nominal | 900 |

| Surface Water Absorption, grams, nominal | <2.5 |

| Bending Radius | 8’ (2438 mm) |

PHYSICAL PROPERTIES

| Length | standard: 4′ (1219 mm) and 8′ (2438 mm) ± 1/4″ (6.4 mm) |

| Width | standard: 4’ (1219 mm) ± 1/8” (3 mm) |

| Thickness | nominal: 5/8” (15.9 mm) ± 1/32” (.8 mm) |

| Weight | nominal: 2.5 (12.2) |

CERTIFICATIONS

Certifications may vary by production location, please contact local representative for more information.

1. The score of 10 in the ASTM D3273 test indicates no mold growth in a 4-week controlled laboratory test. The mold resistance of any building product when used in actual job site conditions may not produce the same results as were achieved in the controlled, laboratory setting.

2. Tested in accordance with ASTM E661.

3. Tested in accordance with ASTM C1177.

Resources

Related Products

Need Technical Help?

Gypsum Products

OSB/Plywood Products

Wood Products

Lumber Products

Newsletter Sign Up

Subscribe for the latest news and insights.