DensElement® Sheathing

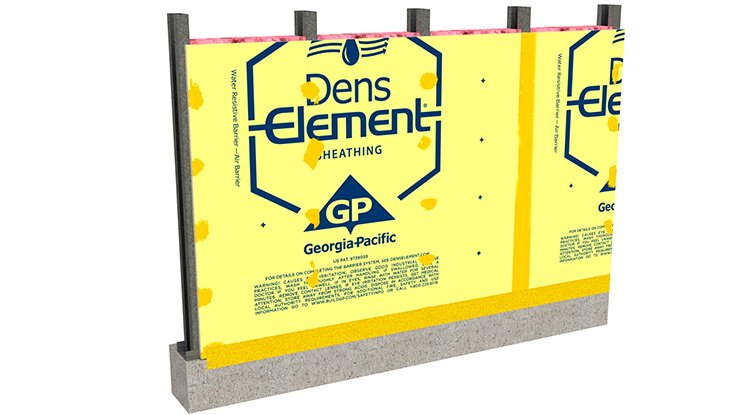

- An integrated water-resistive and air barrier (WRB/AB) sheathing system can be installed in all weather conditions for faster job completion.

- Manufactured to meet the stringent ASTM C1177 standard.4

- Approved flashing/transition accessories include DensDefy® Liquid Flashing and DensDefy® Transition Membrane.

- Offers superior vapor permeance of >30 (wet cup), >20 (dry cup) for a 5/8( (15.9mm) thickness.

- Has a flame spread and smoke development rating of 0/0, ensuring maximum safety.

Product Details

Our system embraces the elements, encouraging quicker dry-in of the structure and improved resistance to moisture and air infiltration. Furthermore, the DensElement® Barrier System simplifies quality control, taking away the challenges often associated with building wraps and membranes.

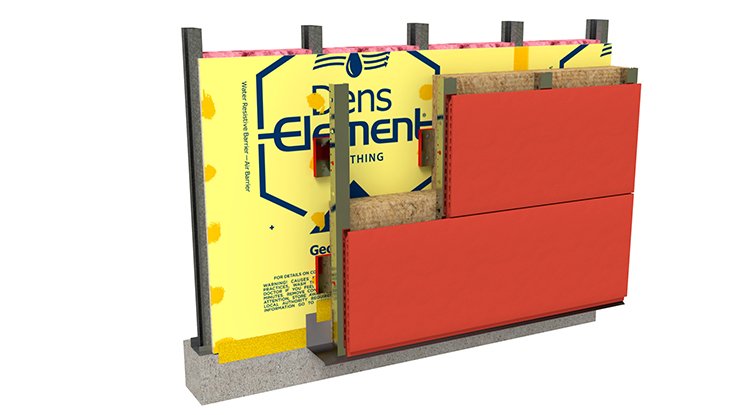

Experience the efficiency and durability of the DensElement Barrier System, designed to simplify and speed up your construction timeline. Whether you’re on the jobsite or pre-designing at a fabrication facility, this versatile system resists standard weather conditions and effectively prevents uncontrolled air movement. Paired with DensDefy® Accessories, it streamlines your installation process, keeping projects on time and well-coordinated.

Trust in the engineering behind the DensElement® Sheathing, a cherished solution amongst contractors, builders, and architects. This sheathing embodies endurance, air and water resistance, and outstanding vapor permeance for robust, energy-efficient, and sustainable structures. Exceeding industry standards, this sheathing ensures your project stands the test of time, providing trusted protection and enduring brilliance.

FEATURES AND BENEFITS

- Dual Barrier System: Certified as both an air barrier and water-resistive barrier, rigorously tested against ICC-ES AC212, AC310, ASTM E2178, and ASTM E2357 standards.

- Superior Fire Resistance: Achieves a flame spread and smoke development rating of 0/0 (ASTM E84).

- Exceptional Vapor Permeance: Boasts vapor permeance of >30 (wet cup) and >20 (dry cup) as per ASTM E96.

- Durability Meets Versatility: Designed to thrive in commercial and residential construction across various climate conditions.

- Fire-resistance: Enhance safety and meet codes as 5/8″ non-combustible Type X sheathing, ideal for all building needs with superior fire resistance.

Product Specifications

PERFORMANCE ATTRIBUTES

| R Value | °F•ft2•hr/BTU (m2•K/W): 0.67 (0.118) |

| Humidified Deflection1, 4 | ≤1/8″ (3 mm) |

| ASTM Type | ASTM C1396; ASTM C1629; ASTM C473; ASTM E136; ASTM E84 |

| Flame Spread & Smoke Development | 15 & 0 (product dependent) |

| Fire Rating | Type X |

| Mold Resistance | No (10/10) |

| Compressive strength | min. 500 psi (3445 kPa) |

| Racking strength,7 lbs./ft. (dry) (N/m) (Ultimate – not design value) | >654 (9544) |

| Flexural strength2, parallel, lbf. (N) (4’ weak direction) | ≥100 (445) |

| Linear expansion with moisture change in/ in/%RH (mm/mm %RH)5 | 6.25 x 10-6 |

| Surface burning characteristics1 flame spread/smoke developed | 0/0 |

| Coefficient of thermal expansion in/in/°F (mm/mm/°C)11 | 8.5 x 10-6 (15.3 x 10-6) |

| Permeance2, US perms (grained/ft2 .hr.inHg) | >20 (dry cup) >30 (wet cup) |

PHYSICAL ATTRIBUTES

| Length | standard: 8′ (2438 mm), 10′ (3048 mm), 12′ (3658 mm) ± 1/4″ (6.4 mm) |

| Width | nominal: 4′ (1219 mm) ± 3/32″ (2.4 mm) |

| Thickness | nominal: 5/8″ (15.9 mm) ± 1/64″ (0.4 mm) |

| Weight | 2.0 (9.0) lbs./sq. ft., nominal (kg/sq.m) |

| Edge | Smooth Wall; Square Edge; Tapered Edge |

CERTIFICATIONS

1 Tested in accordance with ASTM C473

2 Tested in accordance with ASTM E96 (wet cup method)

3 Tested in accordance with ASTM C518 (heat flow meter)

4 Specified values per ASTM C1177

5 As stated by Gypsum Association GA-235

Resources

Related Products

Need Technical Help?

Gypsum Products

OSB/Plywood Products

Wood Products

Lumber Products

Newsletter Sign Up

Subscribe for the latest news and insights.